Integrated Facilities Management Case Study

Improving Site-Wide Reliability for a Multinational Manufacturing Client

Bay Enterprises delivers smarter, more reliable IFM solutions backed by in-house engineering and Ireland’s only Industrial Repair Centre for IFM provider's.

Client Profile

Bay Enterprises partnered with a multinational client operating a large and diverse equipment base. The client was experiencing frequent intermittent electrical faults across several production assets, which were impacting uptime, diagnostics, and operational efficiency.

Our Solution

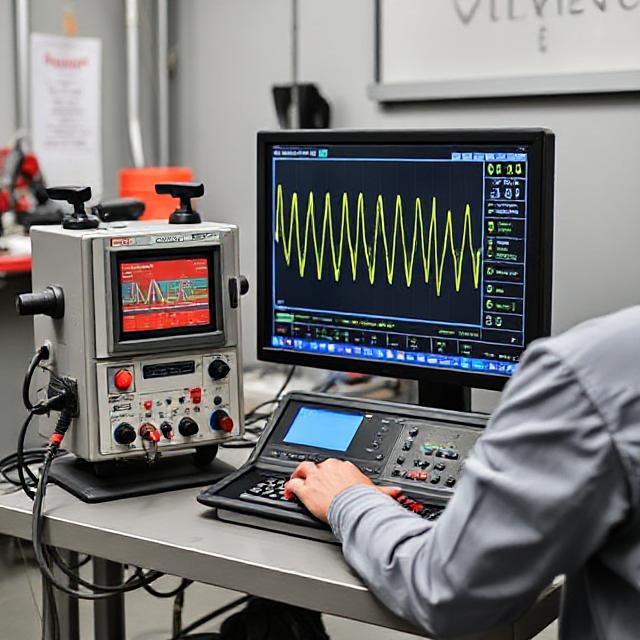

Bay Enterprises leveraged its Industrial Repair Centre to conduct advanced diagnostic testing using the SKF TKED 1 Electric Discharge Detector, revealing multiple equipment installation and reliability issues within the existing asset base. Our onsite Integrated Facilities Management team were heavily involved by providing key information

Our approach included:

- A site-wide Root Cause Analysis (RCA) led by our reliability team

- Development of a technician “cheat sheet”, mapping failure modes and response actions

- Assigning RCA outcomes and responsibilities across maintenance, engineering, and operations teams

- Use of the Apollo RCA methodology for consistent, systematic failure resolution

This structured approach helped the client proactively manage faults, improve training, and instill a stronger reliability culture across the site.

Client Objectives

- Identify and eliminate recurring electrical issues

- Improve site-wide technical knowledge and reliability

- Reduce unplanned downtime across critical systems

- Provide technicians with a structured approach to fault resolution

The Results

- 400+ hours of reduced downtime

- Improved asset reliability and fault response time

- Greater technician autonomy through structured RCA reference tools

- Shared site-wide knowledge that previously did not exist

Why Bay Enterprises?

Testimonials

"Our company have been working with Bay Enterprises for more than 15 years. Now as one of our trusted suppliers and partners they have developed the knowledge and understanding of our business to identify problems independently. They also have the capabilities to develop solutions and execute and implement them. I would have no hesitation in recommending Bay Enterprises as a partner to any other business"

Senior Manager at a Leading Medical Device Manufacturer based in Limerick

"We have worked with Bay Enterprises on a variety of maintenance projects over the past 6 years. We have always found them to be very flexible when called upon, often providing us with fast turn around and solutions for parts critical to our business. It is a great advantage to us here in Boston Scientific to have such a competent service provider which is locally available."

Boston Scientific